Healthcare settings, warehouses, homes, and hospitality depend on casters for efficiency. They aid patient care by helping staff maneuver equipment quickly and quietly. Choosing the right design and size reduces risks, boosts efficiency, and ensures safety. Casters are vital for ergonomics and productivity, beyond just their appearance.

Casters are essential for the safe, efficient movement of everyday objects, from office chairs to medical equipment. Choosing the right caster prevents floor damage, reduces noise, and minimizes strain during moving tasks. For example, shopping cart wheels must glide smoothly across different surfaces in a store, supporting heavy loads while being quiet and easy to push. This is why selecting appropriate casters is critical for both comfort and safety.

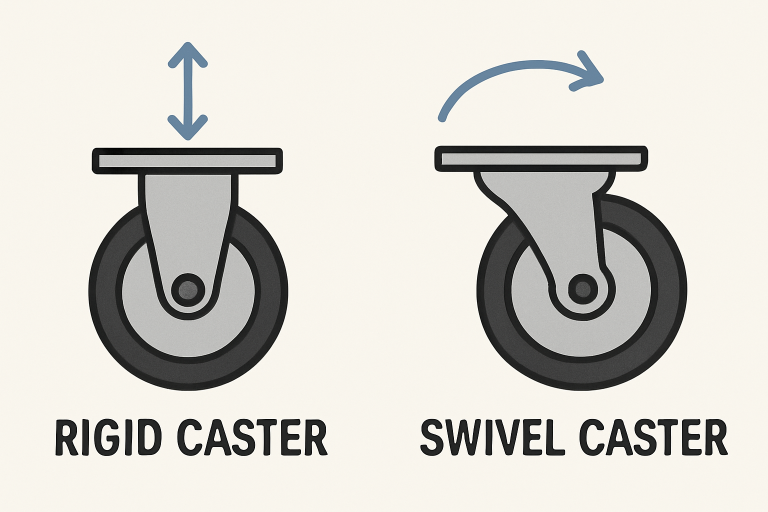

Types of Casters Explained

Casters are either rigid or swivel. Rigid casters move straight, providing stability where turning isn’t needed. Swivel casters rotate 360 degrees, enabling smooth turns and maneuvering in tight spaces. When choosing, consider how often the cart or equipment needs to pivot or move along complex paths. Caster wheels are made from hard rubber for carpets or gripless surfaces, soft wheels for quiet, floor-protecting movement on tile or hardwood, and specialty materials like polyurethane, stainless steel, or nylon for chemical or thermal resistance. Larger wheels help in industrial settings or on uneven surfaces by offering shock absorption and more straightforward obstacle navigation. OSHA highlights how ergonomic material handling reduces injuries and boosts productivity, emphasizing proper caster use to prevent strain and repetitive injuries.

Key Factors to Consider When Selecting Casters

Casters are rated for specific load limits, so it’s crucial to determine the heaviest anticipated load and choose casters that provide a comfortable margin above that weight to avoid failure. Matching wheel material with the floor surface type is essential for optimal performance and floor protection. Choose stainless steel or plastic casters that resist corrosion for areas prone to moisture or chemicals. Libraries, hospitals, or office environments often require casters that reduce rolling noise to maintain a peaceful atmosphere. Consulting ergonomics guidelines can help ensure user health and safety.

Improving Workplace Safety with Proper Casters

Choosing the right casters is vital for workplace safety. Small or unsuitable wheels can get stuck or wear out, causing accidents. Larger casters help carts roll over cables, floor changes, or debris, reducing jolts that could cause loss of control. OSHA recommends preventive measures like this to lower injuries and boost reliability. Regular checks, especially after seasons or shifts, can reveal hazards early. Even a sticky or wobbly wheel can make moving heavy loads harder, risking strain and downtime.

Special Uses of Casters Across Industries

Casters adapt to diverse industry needs. The entertainment sector uses ultra-quiet wheels for cameras to prevent noise; hospitals require easy-to-disinfect, quiet casters to reduce patient stress; and food service relies on heat-resistant casters for oven racks. In disaster response and military logistics, rugged, high-capacity casters enable quick transport of heavy loads in tough conditions. These examples highlight the importance of understanding specific needs for optimal caster performance.

Maintenance Tips for Caster Longevity

To ensure smooth and reliable mobility, regularly remove dirt and debris from caster wheels, tighten bolts, axles, and mounting hardware, and lubricate swivel bearings and pivot points. Ensure wheel wear or cracking is promptly replaced to prevent floor damage or safety incidents. Consistent maintenance extends the useful lifespan of casters, saving money on replacements and repairs.

Modern Innovations in Caster Design

Advancements in caster design now include safety and hygiene features for modern needs. Automatic locking enhances stability on rough surfaces. Antimicrobial coatings reduce bacteria on equipment used across facilities. IoT-enabled casters monitor usage, track movement, and send maintenance alerts, boosting warehouse efficiency. Keeping up with new options helps organizations maximize caster technology for better mobility and safety.

Conclusion: Maximizing Efficiency and Safety with the Right Casters

Casters are essential components that improve safety, efficiency, and ergonomics in homes, workplaces, and industry. Choosing the right type, size, and material ensures smooth operation, reduces strain, and protects equipment and floors. Regular maintenance and innovations like antimicrobial coatings or IoT monitoring extend lifespan and optimize performance. Investing in proper casters and maintaining them enhances workflow, prevents accidents, and makes movement safer and more reliable.